Abstract

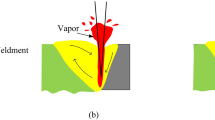

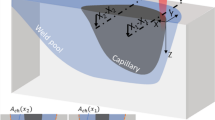

The time dependent heating and cooling velocities are investigated in this paper. The temperature profile is found by using a keyhole approximation for the melted zone and solving the heat transfer equation. A polynomial expansion has been deployed to determine the cooling velocity during welding cut-off stage. The maximum cooling velocity has been estimated to be V max ≈ 83°C s−1.

Similar content being viewed by others

Abbreviations

- D :

-

Thermal diffusivity (m2 s−1)

- h :

-

Keyhole height (m)

- k :

-

Thermal conductivity (Wm−1 K−1)

- N 0 :

-

Prefixed integer

- P :

-

Fluid pressure at mean temperature (Pa)

- Q v :

-

Power per unit volume (Wm−3)

- T :

-

Absolute temperature (K)

- T 0 :

-

Maximum absolute temperature (K)

- T ∞ :

-

Room absolute temperature (K)

- α q :

-

Boubaker polynomials minimal positive roots (dimensionless)

- \( \varpi \) :

-

Constant (dimensionless)

- ρ :

-

Density (Kg m−3)

- γ :

-

Heat capacity ratio (dimensionless)

- ξ q :

-

Real coefficients (dimensionless)

References

Singh RK, Narayan J (1990) Pulsed-laser evaporation technique for deposition of thin films: physics and theoretical model. Phys Rev B 41:8843–8859

Anisimov SI, Luk’yanchuk BS, Luches A (1996) An analytical model for three-dimensional laser plume expansion into vacuum in hydrodynamic regime. Appl Surf Sci 96–98:24–32

Koopman DW (1971) Langmuir probe and microwave measurements of streaming plasmas generated by focused laser pulses. Phys Fluids 14:1707–1716

Toftmann B, Schou J, Hansen TN, Lunney JG (2000) Angular distribution of electron temperature and density in a laser-ablation plume. Phys Rev Lett 84:3998–4001

Weaver I, Martin GW, Graham WG, Morrow T, Lewis CLS (1999) The langmuir probe as a diagnostic of the electron component within low temperature laser ablated plasma plumes. Rev Sci Instrum 70:1801–1805

Doggett B, Budtz-Joergensen C, Lunney JG, Sheerin P, Turner MM (2005) Behaviour of a planar langmuir probe in a laser ablation plasma. Appl Surf Sci 247:134–138

Chaouachi A, Boubaker K, Amlouk M, Bouzouita H (2007) Enhancement of pyrolysis spray disposal performance using thermal time-response to precursor uniform deposition. Eur Phys J Appl Phys 37:105–109

Ghanouchi J, Labiadh H, Boubaker K (2008) An attempt to solve the heat transfer equation in a model of pyrolysis spray using 4q-order Boubaker polynomials. Int J Heat Tech 26:49–52

Awojoyogbe OB, Boubaker K (2009) A solution to Bloch NMR flow equations for the analysis of homodynamic functions of blood flow system using m-Boubaker polynomials. Curr Appl Phys 9:278–283

Boubaker K (2007) On modified Boubaker polynomials: some differential and analytical properties of the new polynomials issued from an attempt for solving bi-varied heat equation. Trends Appl Sci Res 2:540–544 (by Academic Journals ‘aj’ New York)

Labiadh H (2007) A Sturm-Liouville shaped characteristic differential equation as a guide to establish a quasi-polynomial expression to the Boubaker polynomials. J Differ Equ Control Processes 2:117–133

Gallusser R, Dressler K (1971) Application of the coulomb approximation to the Rydberg transitions of the NO molecule. Zeitschrift für Angewandte Mathematik und Physik (ZAMP) 22:792–794

Armstrong BH, Purdum KL (1966) Extended use of the coulomb approximation: mean powers, a sum rule, and improved transition integrals. Phys Rev 150:51–58

Paul A, Debroy T (1988) Free surface flow and heat transfer in conduction mode laser welding. Metall Mater Trans B 19:851–858

Andreassen E, Myhre OJ, Oldervoll F, Hinrichsen EL, Grøstad K, Braathen MD (1995) Nonuniform cooling in multifilament melt spinning of polypropylene fibers: cooling air speed limits and fiber-to-fiber variations. J Appl Polym Sci 58:1619–1632

Belcher SL (2007) Practical guide to injection blow molding, ISBN 0824757912, 9780824757915, CRC Press, Boca Raton

Santos CAC, Quaresma JNN, Lima JA (2001) Convective heat transfer in ducts: the integral transform approach: the integral transform approach, ISBN 8587922238, 9788587922236, E-papers Servicos Editoriais Ltda

Mughal MP, Fawad H, Mufti R (2006) Finite element prediction of thermal stresses and deformations in layered manufacturing of metallic parts. Acta Mech 183:61–79

Dowden J, Postacioglu N, Davis M, Kapadia P (1987) A keyhole model in penetration welding with a laser. J Phys D Appl Phys 20:36–44

Semak VV, Bragg WD, Damkroger B, Kempka S (1999) Transient model for the keyhole during laser welding. J Phys D Appl Phys 32:61–64

Ki H, Mazumder J, Mohanty PS (2002) Modeling of laser keyhole welding: Part II. simulation of keyhole evolution, velocity, temperature profile, and experimental verification. Metall Mater Trans A 33:1831–1842

Rai R, Kelly SM, Martukanitz RP, DebRoy T (2008) A convective heat-transfer model for partial and full penetration keyhole mode laser welding of a structural steel. Metall Mater Trans A 39:98–112

Al-Kazzaz H, Medraj M, Caoand X, Jahazi M (2008) Nd:YAG laser welding of aerospace grade ZE41A magnesium alloy: modeling and experimental investigations. Mater Chem Phys 109:61–76

Kaplan A (1994) A model of deep penetration laser welding based on calculation of the keyhole profile. J Phys D Appl Phys 27(180):5–1814

Lampa C, Kaplan AFH, Powell J, Magnusson C (1997) An analytical thermodynamic model of laser welding. J Phys D Appl Phys 30(9):1293–1299

Jin X, Li L, Zhang Y (2002) A study on Fresnel absorption and reflections in the keyhole in deep penetration laser welding. J Phys D Appl Phys 35:2304–2310

Solana GNegro (1997) A study of the effect of multiple reflections on the shape of the keyhole of the keyhole in the laser processing of materials. J Phys D Appl Phys 30:3216–3222

Wu CS, Wang HG, Zhang YM (2006) A new heat source model for keyhole plasma arc welding in FEM analysis of the temperature profile. Weld J 85:284–289

Yamamoto N, Genma K (2007) On error estimation of finite element approximations to the elliptic equations in nonconvex polygon domains. J Comput Appl Math 199:286–296

Tabata M (2007) Discrepancy between theory and real computation on the stability of some finite element schemes. J Comput Appl Math 199:424–431

Lamba H, Seaman T (2006) Mean-square stability properties of an adaptive time-stepping SDE solver. J Comput Appl Math 194:245–254

Chantasiriwan S (2000) Inverse determination of steady-state heat transfer coefficient. Int Comm Heat Mass Transf 27(8):1155–1164

Erdogdu F (2005) Mathematical approaches for use of analytical solutions in experimental determination of heat and mass transfer parameters. J Food Eng 68:233–238

Kusiak A, Battaaglia JL, Marchal R (2005) Influence of CrN coating in wood machining from heat flux estimation in the tool. Int J Therm Sci 44:289–301

Cohen K, Siegel S, McLaughlin (2006) A heuristic approach to effective sensor placement for modelling o a cylinder wake. Comput Fluids 35:103–120

Chen CK, Wu LW, Yang YT (2006) Application of the inverse method to the estimation of heat flux and temperature on the external surface in laminar pipe flow. Appl Therm Eng 26:1714–1724

Benjamin SF, Roberts CA (2002) Measuring flow velocity at elevated temperature with a hot wire anemometer calibrated in cold flow. Int J Heat Mass Transf 45:703–706

Uselton S, Ahrens J, Bethel W, Treinish L (1998) Multi-source data analysis challenges. In: Proceedings of IEEE Vis 98(VIZ98)

Emery AF, Nenarokomov AV, Fadale TD (2000) Uncertainties in parameter estimation: the optimal experiment design. Int J Heat Mass Transf 43:3331–3339

Refsgaard JC, Henriksen HJ (2004) Modelling guidelines terminology and guiding principles. Adv Water Resour 27:71–82

Lauwagie T, Sol H, Heylen W (2006) Handling uncertainties in mixed numerical-experimental techniques for vibration based material identification. J Sound Vib 291:723–739

Ramroth WT, Krysl P, Asaro RJ (2006) Sensitivity and uncertainty analysis for FE thermal model of FRP panel exposed to fire. Compos Part A 37:1082–1091

Hsu PT (2006) Estimating the boundary condition in a 3D inverse hyperbolic heat conduction problem. Appl Math Comput 177:453–464

Acknowledgment

The authors would like to acknowledge help and assistance from Associate Professor Karem Boubaker from University of Tunisia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tabatabaei, S.A.H.A.E., Zhao, T., Awojoyogbe, O.B. et al. Cut-off cooling velocity profiling inside a keyhole model using the Boubaker polynomials expansion scheme. Heat Mass Transfer 45, 1247–1251 (2009). https://doi.org/10.1007/s00231-009-0493-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-009-0493-x