Kevin Tully was in Syracuse, N.Y., studying for the bar exam when a friend came pedaling up to his apartment on a bicycle. Not just any bicycle but a one-of-a-kind machine she herself had created on a hip, design-it-yourself website owned by Republic Bike. "She went online and picked out all the colors and parts," he says. "She was really enthusiastic about the bike because it represented her sense of style."

As a lifelong guitar player, Tully identified with that sense of pride. He was no Jimi Hendrix, but the two instruments in his home ranked among his most prized possessions. How great would it be, he wondered, if they could truly reflect his personal taste?

And so, over Thanksgiving in 2011, Tully approached his high school friend Dave Barry, a fellow guitar enthusiast, with the idea of launching a business. "Your guitar is kind of an extension of yourself, and guitar players are creative by nature," Barry says. "We wanted to give people the opportunity to create their own guitar."

Five months later the duo unveiled Moniker Guitars using $25,000 in seed funding from the business incubator at Barry's alma mater, Northeastern University. The company now employs six people and operates out of a shared work space in Austin, Texas, turning out a dozen or so electric guitars a week. If you want a cherry-red model with a crisp, white racing stripe, Moniker will make it for you. Zebra stripes? That too. Polka dots? Yep. Even logos, photos, and type. The company offers three body styles, five stains, 17 paint colors, and limitless graphic options.

Custom-made instruments are nothing new, but for years few musicians—beyond those with platinum record sales—had the money or the pull to create a signature style. Now, using online design tools and advanced manufacturing techniques, Moniker has figured out how to produce high-quality instruments with artistic touches for $850 to $1250—roughly what one would pay for a generic model in a store.

Moniker has joined a growing movement known as mass customization. In an era when technology has made it possible to personalize almost anything, examples of such items abound: sneakers, cellphone cases, Scion cars, messenger bags, toolboxes, T-shirts, couches, bed linens, coffee mugs, drapes, boots, chocolate bars, and M&M's. In his book, Custom Nation, Anthony Flynn argues that this shift in product development is so sweeping that it will one day rival the impact of the industrial revolution. Flynn witnessed the power of the trend after he founded YouBar, a company that enables consumers to create their own energy bars. He was trying to target people with food allergies and other health issues, but the audience turned out to be much broader. Young consumers have come to expect one-of-a-kind experiences, he says: on-demand TV and movies, plus tailored news feeds (Facebook and Twitter), music-streaming sites (Pandora and Spotify), and dating services (Match.com). With the advance of 3D printers, there will soon be no end to what people can personalize.

Kent Deverell is the CEO of the Web development company Fluid, which has created customization sites—aka configurators—for The North Face, Reebok, L.L.Bean, Brooks Brothers, and Oakley sunglasses. "It's probably the fastest-growing area of our business," he says. For today's retailers, he explains, personalized products are an ideal way to compete with Amazon, the king of bargains and selection. "People who buy customized products are your best customers," Deverell says. "They engage with your brand, they're willing to pay more, and they have a higher level of satisfaction. If I buy a customized shoe from Nike, I'm 45 percent more likely to recommend that brand to another person than someone who just bought a shoe off the shelf."

And as startups such as Moniker attest, it's far easier to enter the market these days than it was in 1999, when Nike reportedly spent $30 million to develop the configurator for its groundbreaking NIKEiD program. Tully says he built Moniker's configurator for about $10,000 with the help of a friend and a freelance developer. It took roughly three months of round-the-clock work on Photoshop to get the images just right. "Our main goal was to keep the site as clean and simple as possible," Tully says. "If my mother couldn't use it, we were doing something wrong."

Streamlining production was the next challenge. "When we started, we realized that we live in an instant-gratification society," Barry says. "People want things now. We had to figure out a way to produce high-quality guitars with relatively fast turnaround."

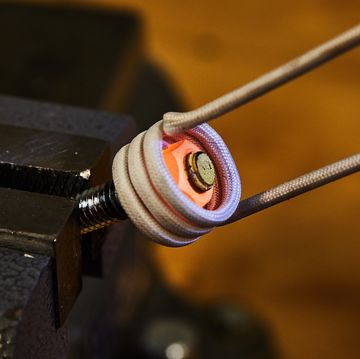

A CNC mill allowed the team to precisely replicate each body, including the cavities in Moniker's semihollow models. Most guitar makers prime the wood—in this case alder—with a nitrocellulose clear coat that can take a month or more to dry. After looking around, Moniker discovered a clear polyester resin manufactured by Simtec that cures in minutes under ultraviolet light. "You have to wear a protective suit, which is awesome in the summer when it's 110 degrees outside," Tully says.

Instead of standard solvent-based spray paints, which are not only slow to dry but can run afoul of environmental regulations, the company uses a water-based paint low in volatile organic compounds, manufactured by PPG Industries. (Ferrari and Lamborghini have also adopted it.) Moniker also uses advanced printing techniques, including a vinyl plotter that makes spray-paint stencils from vector files built in Adobe Illustrator, to create type and graphics. If pressed, Tully's team could probably assemble a guitar in 24 hours, though standard delivery is four weeks.

It's still too soon to predict Moniker's success—Tully will not divulge sales figures—but the early feedback is promising. The company's guitars have been featured on MSNBC and showcased at the South by Southwest and Bonnaroo music festivals. During a 2013 Kickstarter campaign, Moniker raised $60,000 from 155 backers in a single month. And Tully's guitars are now popping up in the hands of artists on the Austin music scene. Tyler Temple of American Dischord even had the company's logo tattooed on his hand.

Kyle Bailey, a guitar aficionado who runs an online marketing company in Austin, has visited Moniker's workshop to test out the wares. In an online review, he praised its pickups, particularly the top-of-the-line Seymour Duncan options—noting the guitars' string-to-string detail. "That's one of the things that makes high-end Les Paul guitars sound so clean," he says. "You can hear each string very clearly. Moniker's electronics achieve that. They're very responsive."

Tully would be happy simply to engage his version of the guitar hero. "I don't mean U2 or Led Zeppelin," he says. "I mean working musicians who are passionate about what they do but have to grind it out to make a living." And it's not all about advanced technology. "The end goal is to have the guitars look classic," Tully says. "Not like something from the future but like what guitar traditionalists would appreciate."